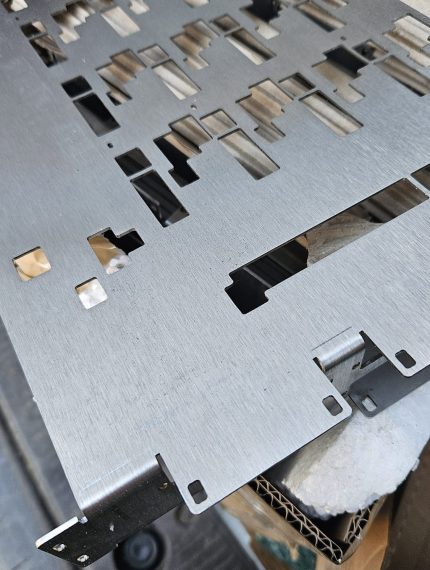

PROFESSIONAL LASER CUTTING SERVICES

Precision Laser Cutting for High-Performance Industrial Applications

We use advanced laser cutting equipment to ensure high precision and fast execution times.

- High-Accuracy Laser Cutting for Steel, Stainless, and Aluminum.

- Integrated with Full Machining & Fabrication.

- ISO-Compliant Quality and Traceability.

- Trusted by aerospace, automotive, food processing, and machinery manufacturers.

Laser cutting services tailored for industrial components and assemblies.

Types of materials we can laser cut:

Steel

Steel laser cut parts.

Stainless steel

Stainless steel laser cut parts.

Aluminum

Aluminum laser cut parts.

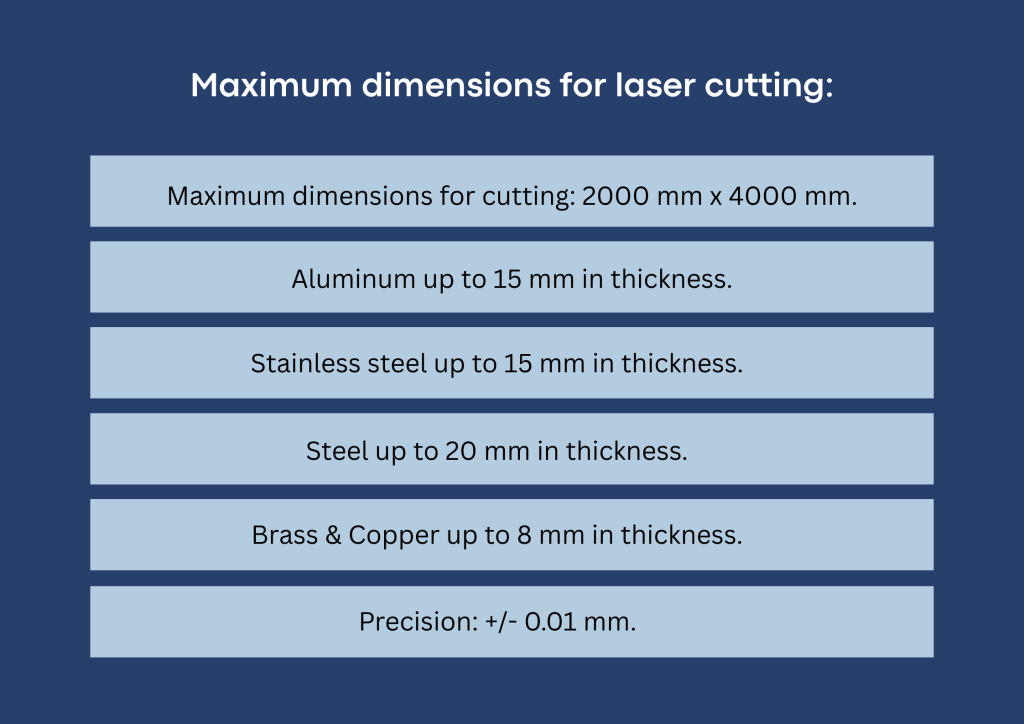

Laser cutting capabilities

Sheet metal laser cutting services for various industries

- Machinery manufacturing

Laser cut sheet metal parts for machine components, both precision and large parts: machine frames & base panels, mounting plates and brackets, maintenance panels, ducts and channels.

- Aeronautics:

In the aeronautics industry, sheet metal parts are crucial for both structural and non-structural applications due to their light weight, strength-to-weight ratio, and formability.

- Automotive industry

The automotive industry relies heavily on sheet metal parts, both for structural and non-structural components, across vehicle manufacturing, tooling, and automation equipment: chassis & subframe components, tooling & equipment enclosures.

- Agriculture

Machine covers & housings, chutes, funnels, and guards, grain tank components & hoppers, silos, filters, and small size components.

- Food Industry

Conveyor covers & machine enclosures, hoppers, bins & chutes, machine frames & protective guards.

- Pharma Industry

Machine enclosures & cabinets, conveyor covers & transfer tunnels, mounting frameworks.

What is laser cutting?

What are the advantages of laser cutting?

- High precision and accuracy

- Decreased production time

- Minimal material waste

- Versatility