INOTECH Machining is a Romanian company specializing in the manufacturing of CNC machined parts and welded subassemblies.

We operate the most recent machining technology to provide top-quality mechanical components to our customers.

Thanks to the quality we deliver, INOTECH Machining has earned a great reputation on the European market.

We operate a modern workstation and advanced equipment.

Fiscal value

Completed Projects

Experience

100% European

We specialize in:

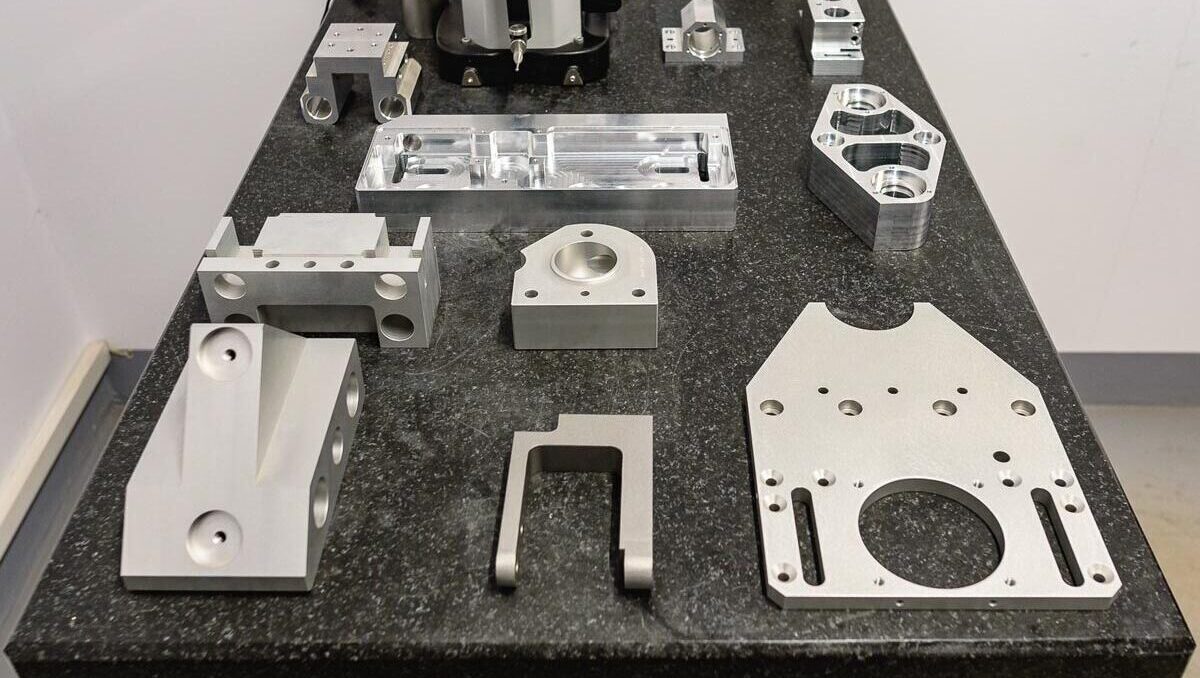

We use technologically advanced CNC machines

to produce first-class CNC parts.

- 3-axis CNC milling machines,

- 4-axis CNC milling machines,

- 5-axis CNC milling machines.

Maximum dimensions:

- 10 x 10 x 10 mm – 2000 x 10000 x 1500 mm

- Tolerances: +/- 0.01 mm, 0.02 mm, 0.05 mm.

Maximum dimensions for CNC turning:

- Diameter: 10 – 1000 mm

- Length: 100 – 10000 mm

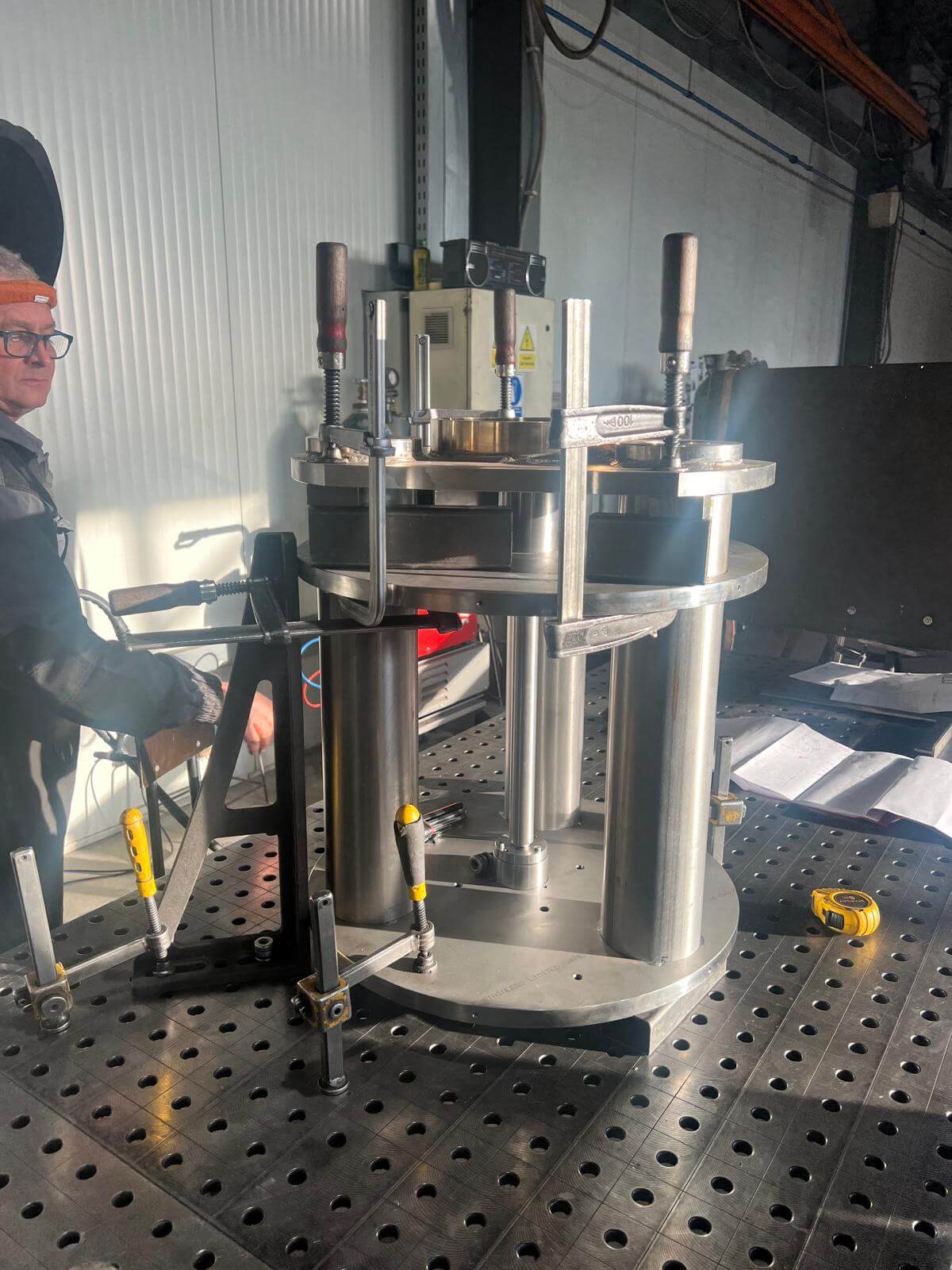

We can weld from large structures to small parts that require increased precision.

Welding is performed in a workshop hall of 6.000 sqm with cranes up to 50 tons.

- Welding processes: MIG-MAG and WIG (TIG).

- Welding in steel, stainless steel and aluminum.

- Quality check of the welds: penetrating liquids, magnetic powders or ultrasonic tests, if needed.

- Geometrical control on place with laser tracking.

We perform various bending procedures based

on our client’s needs and specifications,

including:

- Sheet metal bending,

- CNC tube bending,

- And bending of elements obtained through other technological operations.

INOTECH offers laser cutting services for stainless

steel, steel, aluminum, brass, and copper sheets.

We use advanced laser & plasma cutting

equipment to ensure high precision and fast

execution times.

Surface treatments (3500 x 3500 x 13000 mm):

- Anodizing,

- Zinc plating,

- Blackening,

- Phosphating,

- Electrostatic powder coating,

- Liquid paint.

- Stainless steel passivation

The assembly service has been set up to support our customers’ high demand for pre-assembled sub-assemblies.

We employ various assembly techniques depending on the materials, characteristics of the components and destination of use. Assembling is performed in a dedicated assembly hall entirely dedicated to the assembly of parts.

- 3D control,

- Laser tracking.

We’ve optimized delivery by making the most of the

weekend time.

The products are dispatched by truck

on Fridays and are delivered to our customers’

locations on Mondays, whether that’s in France,

Germany, Switzerland or anywhere else in Europe.

All-round machined parts.

High-Precision CNC Machined Parts and Welded Assemblies

Heavy Industry

We manufacture machined parts for industrial machinery & heavy equipment.

Aeronautics

INOTECH is ISO 9001-certified and works with EN 9100-certified partners for the aerospace industry.

We manufacture machined welded frames and other specific machined parts for the production and testing departments of aircraft manufacturers and their equipment manufacturers. We have experience in manufacturing mounting and assembly line components, testing equipment parts, and various metal equipment accessories.

Automotive

We manufacture serial and prototype reference fixture frames for checking and assembly, for the interior of a car as well as for the exterior.

We also execute other metal parts for the testing facilities, such as checking fixtures, metal and assembly fixtures, demonstrators, and supports.

Pharma

We manufacture high-precision CNC parts for the medical industry.

Agriculture & Food

The development of the Agriculture & Food sector led to an increased need for CNC metal parts.

INOTECH supports this industry by supplying it with impeccable CNC components and complex machined structures.

Research

INOTECH supports the research sector in overcoming challenges and setting new standards by providing first-class metal machined parts.

We have experience in manufacturing unique machined components and assemblies for science research laboratories and testing facilities.