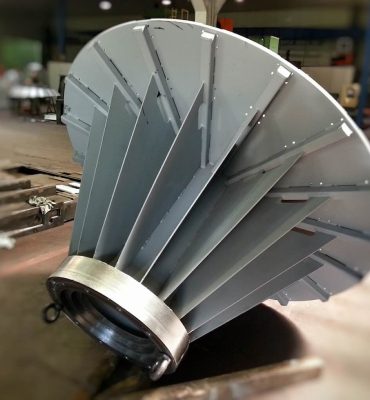

WELDING SERVICES

High-Precision Welding Services for Industrial Applications

One-stop shop for all your projects: full range milling and turning services complemented by high-quality welding services.

We offer precision welding services tailored to the needs of industrial manufacturers across Europe. From MIG and TIG welding to custom weld assemblies, we work with carbon steel, stainless steel, and aluminum to produce high-quality welded components.

Welded metal parts: from large structures to small parts that require increased precision.

Welding capabilities

Welding hall

1600 m² workshop

Cranes up to 50 tons.

Welding processes

MIG-MAG Welding

WIG (TIG) Welding

Quality control of welds

Penetrating liquids.

Magnetic powders or ultrasonic tests.

Geometric inspection with laser tracking.

Types of materials we can weld

Steel

Steel welding

Stainless steel

Stainless steel welding

Aluminum

Aluminum welding

We supply welded components and subassemblies to a wide range of industries.

- Machinery Manufacturing

The machinery manufacturing sector relies heavily on welded components to construct durable, custom-built equipment. Welded assemblies form the backbone of machine frames, enclosures, bases, and mechanical supports, providing the strength and precision needed for heavy-duty industrial operation. Whether for automation, packaging, or specialized production lines, welding ensures structural integrity and long service life.

- Automotive Machine Manufacturers

In the automotive industry, machines that build vehicles require robust welded structures for stability, precision, and efficiency. From robotic welding arms to stamping press frames and conveyor systems, welded parts are essential for building reliable production infrastructure.

- Aeronautics

The aeronautics industry depends on highly engineered machinery to manufacture complex aircraft parts. Welded frames and fixtures support assembly lines, positioning tools, and inspection stations, ensuring stability and exactness. Though not flight components, these weldments are crucial for building aircraft components to strict aerospace tolerances.

- Agriculture

Agricultural equipment manufacturers use welded parts to produce rugged, field-ready machinery. Welding joins structural elements like chassis, arms, and toolbars, ensuring the resilience required in harsh working conditions. Welded assemblies are found in seeding machines, harvesters, sprayers, and trailers — all vital for modern, mechanized farming.

- Food industry

In the food industry, stainless steel welded parts are used to build hygienic and corrosion-resistant processing equipment. From conveyor systems to mixing machine frames and sanitary enclosures, welding is essential to meet food safety standards while delivering structural strength and easy-to-clean surfaces in production lines.

- Pharma Industry

Pharmaceutical equipment must meet the highest standards of cleanliness, precision, and reliability. Welded stainless steel frames and enclosures are widely used in fluid handling systems, cleanroom machinery, and packaging lines. These components support sterile production environments and withstand aggressive cleaning protocols.