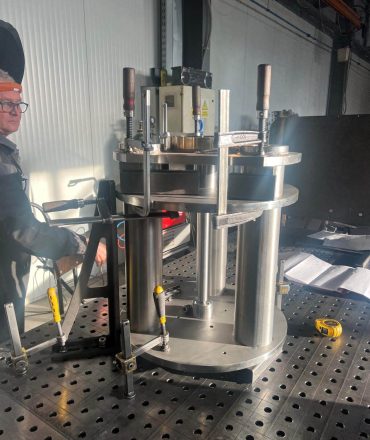

COMPONENT ASSEMBLY SERVICES

From Machined Parts to Finished Assembly — All in One Place.

Full Mechanical Assemblies with Mechanical, Welded, and Sheet Metal Parts

We ensure a professional & smooth mechanical assembly process, seamless integration of the components, and quality checks at every stage.

Save Time and Costs with Our Full-Service Mechanical Assembly Solutions.

Expert Handling of Complex Assemblies

One Supplier — Full Responsibility

1000 m2 Assembly hall

Assembling of the mechanical parts and testing are performed in a 1000 m2 hall.

Measuring & Testing

We run meticulous inspections using dimensional inspection machines, optical scanning units, digital measuring columns, a profile projector, hardness testers and profilometers.

22 years experience

We have more than 20 years of experience working in the field of CNC machining, welding and assembly.

We provide thorough control to ensure compliance and safety.

Dimensional checks

We use precision tools like calipers, micrometers, and coordinate measuring machines (CMM) to ensure every part meets the specified tolerances on technical drawings. Dimensional verification helps prevent assembly issues and guarantees proper fit between components.

Functional testing

We perform functional testing checks to make sure the assembled components work as intended. This can include movement checks, torque or force tests, and leak testing (for fluid assemblies). It ensures that beyond just fitting together, the assembled parts perform correctly under expected use.

Surface finishing inspections

Surface finishing inspections are critical for both aesthetic appearance and functional performance, especially when parts need to move or fit with others. It involves looking for scratches, burrs, sharp edges, corrosion, welding defects, or coating issues (like paint or plating).