Advanced Materials 2026 — CNC Machining Challenges and Manufacturing Strategies

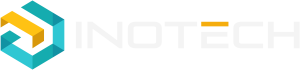

From steels and aluminum to HEAs, MMCs, FGMs, smart and metamaterials, this guide explains properties, machining behavior, AI-assisted strategies, and 2026 trends. Complements the Machining Processes 2025–2026 article. This guide is essential for engineers and buyers looking for custom CNC machining services for various materials, like Steel, Aluminum, Brass, Copper, Titanium, Inconel, HEAs, MMCs, FGMs, Inteligent & Memory Materials, and many others..

Table of Contents: Advanced Materials & CNC Machining Strategies

Why Advanced Materials Matter: 2026 Outlook for CNC Machining and Manufacturing

Advanced materials are reshaping design envelopes and CNC machining strategies. Beyond cost or strength, teams now optimize for temperature stability, corrosion, weight, multi-functionality, and sustainability. Machining must keep pace: hybrid processes, cryogenic cooling, and AI-assisted control are becoming standard practice.

- Key forces: aerospace/EV performance, sustainability mandates, supply volatility.

- Shop-floor shift: from fixed “feeds & speeds” to adaptive machining informed by sensors and digital twins.

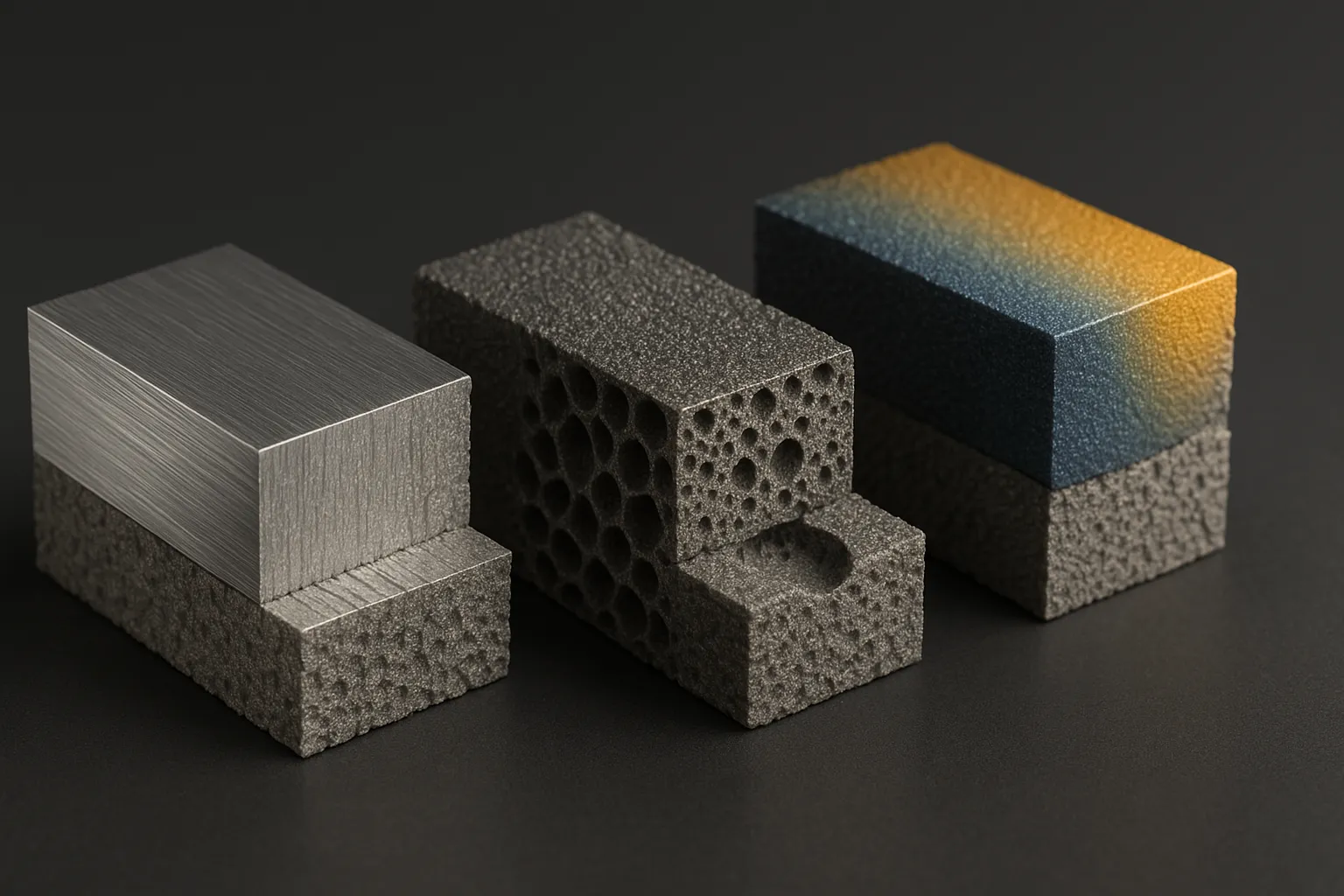

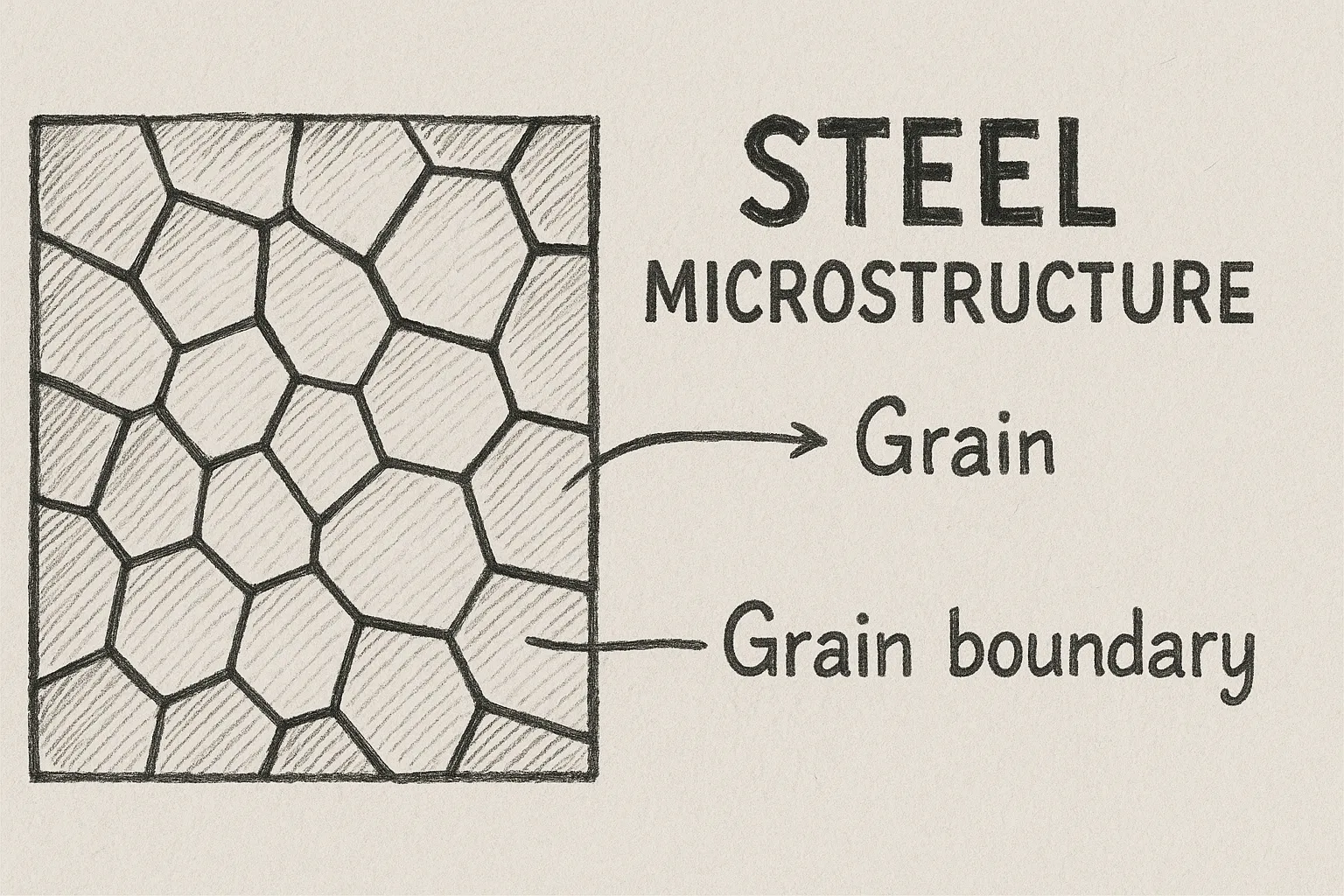

1) Steels: Foundational Materials for CNC Machining and Industrial Applications

Industrial baseline for CNC Machining; properties tailored by carbon and alloying (Cr, Mo, Ni, Mn).

- Description: “Steel” is mostly iron with controlled carbon and alloying elements like chromium or nickel. By changing these amounts and the heat-treat, we can make steels softer/easier to machine or very strong/hard for tools and structures.

- Key properties: ρ 7.7–7.9 g/cm³; hardness 150–300 HV (as-machined); thermal conductivity 45–60 W/m·K; wide strength range.

- Machining challenges: Work-hardening in some stainless grades; built-up edge on mild steel; chatter on long parts.

- Recommended strategy: Coated carbide, flood/MQL; stable fixturing; adaptive feeds to avoid chatter; stainless → sharp geometry + coolant focus.

- Applications: Automotive frames, machine bases, shafts, general hardware.

- Supply Chain Note: Cost-efficient sourcing from EU nearshoring partners (Romania) for custom industrial parts.

2) Aluminum: High-Speed CNC Milling for Lightweight, Precision Components

Lightweight, highly machinable alloys (e.g., 6061, 7075) with excellent conductivity. Ideal for High-Speed CNC Milling.

- Description: Aluminum alloys are aluminum mixed with elements like magnesium, silicon or zinc. They are light, machine very fast, and conduct heat well—great for light structures and heat-sinks.

- Key properties: ρ 2.7–2.9 g/cm³; k 120–200 W/m·K; machinability index ≥1.0; good corrosion resistance (depends on series); low density.

- Machining challenges: Built-up edge (material sticking to the tool), burrs, thin-wall deflection.

- Recommended strategy: Sharp positive rake, polished/DLC tools, high surface speed, MQL/fine flood; support thin sections; tabbed workholding for thin sections.

- Applications: Aerospace structures, EV housings, heat exchangers, precision frames.

- Supply Chain Note: High-speed machining capacity for complex parts (e.g., heat sinks, EV housings) available via European supply chain.

3) Brass & Copper: CNC Machining for High-Conductivity and Corrosion-Resistant Parts

High machinability (brass) and high conductivity (copper); Pb-free alloys increasingly used for CNC Turning and Milling.

- Description: Brass is copper + zinc; it cuts easily and is common in fittings and connectors. Copper is very conductive but “gummy” when cut—needs sharp tools and good lubrication.

- Key properties: Brass ρ ~8.4 g/cm³; k ~110 W/m·K; machinability ~1.2. Copper: very high conductivity, soft/ductile.

- Machining challenges: Copper burrs and tool sticking; Pb-free brass can be a bit harder to machine.

- Recommended strategy: Very sharp tools, light fz, clean lubricant, planned deburring; for copper use polished edges and coolant control; lube and sharp geometry are critical.

- Applications: Electrical connectors, heat-exchanger parts, valves, instrumentation.

- Supply Chain Note: Reliable supply for high-volume custom turned/milled parts via nearshoring partners.

4) Hardened Steels: Hard Turning and Precision Grinding

Heat-treated components (50–64 HRC) finished by grinding or hard-turning (CBN).

- Description: Hardened steels are steels that were heat-treated to become very hard for wear resistance. They are used in molds, dies, and precision guides, and usually need grinding or special cutting tools to finish.

- Key properties: 50–64 HRC; low ductility; k ~20–30 W/m·K.

- Machining challenges: Grinding burn, micro-cracks, residual stress; slow material removal.

- Recommended strategy: CBN hard-turning when possible; acoustic-emission (AE) aided grinding; careful coolant and spark-out; chilled coolant control.

- Applications: Die faces, guideways, high-wear inserts.

- Supply Chain Note: Access to specialized grinding/hard-turning capacity for high-tolerance tooling components.

5) Tool Steels: Machining for Dies, Punches, and Wear Inserts

High Cr-Mo-V; hot hardness and wear resistance; sensitive after heat-treat.

- Description: Tool steels (M2, D2, A2 etc.) contain lots of hard carbides that keep edges sharp at high temperature. Great for making tools, dies and punches.

- Key properties: Excellent hot hardness and wear; moderate thermal conductivity; heat-treat response.

- Machining challenges: Thermal cracking; EDM recast; burrs when still tough.

- Recommended strategy: Wire/sink EDM for shape, grinding for finish, stress-relief cycles, careful polishing; careful polishing.

- Applications: Dies, punches, molds, wear inserts.

- Supply Chain Note: Sourcing of specialized tool steel components for DACH/EU clients.

6) Carbides (Cemented): EDM and Precision Grinding for Custom Tooling

WC-Co composites; too hard for conventional CNC Cutting → grind, EDM, laser finishing.

- Description: “Cemented carbide” is a composite: very hard tungsten-carbide grains glued by a cobalt binder. It’s so hard that we normally grind or EDM it instead of cutting with regular tools.

- Key properties: Extremely hard (tool-class); brittle; low grindability.

- Machining challenges: Micro-cracks, heat checks, slow removal rate.

- Recommended strategy: Resin/cBN wheels with AE-based dressing; pulse-tuned EDM; laser edge polishing; laser polish for edges.

- Applications: Cutting inserts, wear plates, dies.

- Supply Chain Note: Access to EDM and precision grinding for carbide tooling and wear parts.

Note: “Laser polishing & micro-texturing” are surface-modifying steps (no part separation) to improve Ra and edge integrity on WC-Co. They differ from laser cutting, which removes material to create a kerf and separate features. For carbides, prefer ultrafast (ps/fs) pulses to minimize HAZ and cobalt depletion.

7) Nickel Alloys & Superalloys (Inconel, Waspaloy, René): Advanced CNC Strategies for High-Temperature Components

High-temperature strength; low conductivity → heat & wear rise quickly during CNC Cutting.

- Description: Nickel superalloys are nickel-chromium-cobalt based. Tiny, ordered particles called gamma-prime (γ′, an intermetallic phase) strengthen the alloy at high temperature, which is why they survive inside jet engines.

- Key properties: Very high hot strength; k ~10–15 W/m·K; strong work-hardening.

- Machining challenges: Fast heat build-up, notch/tool wear, chip welding.

- Recommended strategy: Cryogenic or high-pressure coolant, constant-engagement HSM, small ae/ap, adaptive peck drilling; high-pressure coolant.

- Applications: Turbines, combustors, hot-gas components.

- Supply Chain Note: Specialized capacity for complex, high-value nickel superalloy parts (aerospace/energy).

8) High-Entropy Alloys (HEAs): Machining Challenges and Strategies

Multi-principal alloys (4–6 elements) stabilized by configurational entropy.

- Description: HEAs mix several main elements (not just one base) so the alloy forms stable structures (FCC/BCC). By tuning the mix, we can target toughness, strength, or low-temperature performance.

- Key properties: High strength/toughness; moderate conductivity; phase-dependent behavior.

- Machining challenges: Variable chip formation; wear depends on phases; heat management is key; high work-hardening.

- Recommended strategy: Coated carbide/PCBN; cryo or controlled MQL; conservative engagement; post-polish; post-polish if needed.

- Applications: Energy, aerospace, cryogenic parts, research tooling.

- Supply Chain Note: Sourcing of advanced material machining capacity for R&D and specialized industrial applications.

9) Titanium Alloys: CNC Machining for High-Specific Strength and Biocompatible Parts

High specific strength; adhesive wear is common; keep heat out of the tool edge in CNC Milling.

- Description: Titanium alloys (like Ti-6Al-4V) combine low weight with high strength. They don’t conduct heat well, so heat stays near the cutting edge—this makes machining tricky.

- Key properties: ρ 4.4–4.6 g/cm³; very low k ~7 W/m·K; strong even when hot; high specific strength.

- Machining challenges: Tool heating, chip welding (BUE), thin wall deflection.

- Recommended strategy: Sharp positive rake; short constant engagement; LN₂/MQL; careful step-over; constant engagement (HSM).

- Applications: Airframes, implants, high-strength fasteners.

- Supply Chain Note: High-precision titanium machining for medical and aerospace components.

10) Inconel (Nickel-Based): Advanced Machining Strategies

Covered under Nickel & Superalloys. Kept here for cross-links and SEO.

- Recommended strategy: Cryogenic turning/milling; small ae/ap; adaptive peck drilling; careful deburr/polish.

11) MMCs — Metal Matrix Composites: PCD Machining for High-Wear Components

Metal base (Al/Ti/Mg) + ceramic reinforcement (SiC, Al₂O₃, B₄C) → highly abrasive. Requires specialized CNC Tooling.

- Description: MMCs are metals with hard ceramic particles inside. The particles give stiffness and wear resistance—but they also grind away your cutting tool like sandpaper.

- Key properties: Density close to matrix; hardness ↑ with reinforcement; anisotropy possible.

- Machining challenges: Tool abrasion, edge chipping, surface tearing; high abrasiveness.

- Recommended strategy: PCD/diamond tools; very small chip thickness; ultrasonic-assisted cutting; polish/micro-EDM finishing; ultrasonic-assisted cutting.

- Applications: Brake parts, structural panels, wear liners.

12) Magnesium Alloys (AZ31, AZ91): High-Speed Machining & Safety

Ultra-light alloys with excellent stiffness-to-weight. Ideal for housings and moving assemblies; requires attention to chip ignition.

- Description: Wrought and die-cast Mg alloys (AZ31/AZ91) used where mass reduction is critical.

- Key properties: ρ ≈ 1.8 g/cm³, high damping, good thermal conductivity, corrosion-prone; chips are combustible.

- Machining challenges: Chip ignition risk, feather burrs, edge tearing in drilling, soft surface easily marred.

- Recommended strategy: Sharp tools (micrograin carbide; PCD for finishing), large rake; high vc, moderate fz; dry/MQL with aggressive chip evacuation; peck drilling; Type-D extinguisher & dedicated chip collection.

- Applications: Electronic housings, mobility brackets, robotics, lightweight frames.

- Supply Chain Note: AZ31 common in plate/bar; AZ91 mostly die-cast; protect from corrosion; handle chips per safety SOP.

13) Cobalt-Chrome (Co–Cr): Wear-Resistant Alloys for Medical & Turbomachinery

High hardness and strong work-hardening; biocompatible. Requires low rubbing, targeted cooling and robust tooling.

- Description: Co-Cr specialty alloys for dental/orthopedic parts and high-temp rotating hardware.

- Key properties: High hot hardness, severe work-hardening, low k (heat piles at the edge), excellent corrosion/biocompatibility.

- Machining challenges: Flank/notch wear, thermal damage, chatter with slender tools; abrasive short chips.

- Recommended strategy: Submicron carbide/PCBN; AlTiN/TiAlN coatings; lower vc, higher fz to cut not rub; small ae; multi-jet HPC; gentle deburr + micro-finish.

- Applications: Crowns/abutments, turbine components, valves, pump parts.

- Supply Chain Note: Medical certifications (e.g., ASTM F75); cast-wrought vs. PM routes; lead times for odd diameters.

14) Engineering Ceramics (Si3N4, SiC, Al2O3): Diamond Grinding & Ultrasonic

Brittle-hard materials with outstanding wear/heat resistance; subtractive routes rely on diamond tooling and controlled damage.

- Description: Structural ceramics used where metals fail in wear/temperature.

- Key properties: Very high hardness & modulus; oxidation resistance; limited toughness (brittle fracture risk).

- Machining challenges: Micro-cracking/chipping, low MRR with conventional cutting, coolant filtration demands.

- Recommended strategy: Oil-based diamond grinding; creep-feed for volume; ultrasonic-assisted or micro-milling with bonded diamond; small fz, filtered coolant; spark-out for integrity.

- Applications: Guides/rollers, pump components, thermal shields, high-temp tooling.

- Supply Chain Note: Net-shape press/sinter + finish grind; long lead times for dense blanks and diamond wheels.

15) High-Performance Polymers (PEEK, PEI/ULTEM, PAEK): Clean-Cut & Temperature Control

Engineering thermoplastics for harsh environments; machining must avoid smearing, thermal drift and fuzzing.

- Description: High-temperature polymers replacing metal in weight-critical systems.

- Key properties: High Tg/Tm, good dimensional stability, vibration damping; properties shift with heat/moisture.

- Machining challenges: Smearing/melting, soft burrs and fuzzy edges, thermal deformation.

- Recommended strategy: Razor-sharp, polished-edge tools (uncoated carbide; diamond for finish); moderate vc, adequate fz; air/MQL cooling; large clearance; pre-dry stock (80–120 °C).

- Applications: Aero interiors, medical devices (non-implant), electrical insulation and housings.

- Supply Chain Note: Lot traceability; filled grades (GF/CF) change cutting windows and tool selection.

16) Fiber Composites (CFRP/GFRP & Stacks): Delamination-Free Drilling & Milling

Anisotropic laminates with abrasive fibers; avoid delamination and fiber pull-out, manage dust and heat.

- Description: UD/woven CFRP/GFRP laminates with polymer matrices; include Ti/Al stacks in aerospace.

- Key properties: Anisotropy, layered structure, high abrasiveness, tendency to delamination and fiber pull-out.

- Machining challenges: Entry/exit delamination, rapid tool wear, fine dust (HSE), thermal damage on stacks.

- Recommended strategy: PCD/diamond-coated cutters; special drill points (spurs/high point angle); sacrificial backers; high vc, moderate fz; HEPA extraction; for Ti/CFRP stacks use staged ops or hybrid tools.

- Applications: Aero skins, ribs, auto lightweight parts, sports equipment, robotics arms.

- Supply Chain Note: Tight ply-thickness tolerance; lot variability; MSDS & dust control required.

17) FGMs — Functionally Graded Materials: Adaptive CNC Machining

Composition/property transitions (e.g., metal→ceramic) inside a single part. Requires Adaptive CNC Machining.

- Description: FGMs change composition gradually from one side to the other, like metal on one face and ceramic near the surface. That way you can get strength where needed and wear/heat resistance where it matters.

- Key properties: Hardness/ductility vary with depth; local thermal conductivity changes.

- Machining challenges: Cutting force jumps at interfaces; unpredictable wear zones; composition gradient.

- Recommended strategy: Layer-aware feeds; map-based finishing; in-situ inspection (vision/AE); map-based finishing.

- Applications: Thermal barriers, wear-graded seals, biomedical stems.

18) Smart & Self-Sensing Materials: Low-Stress Machining

Materials that respond to heat, stress, electricity/magnetism, or light (SMA, SMP, piezo, EAP). Requires Low-Stress CNC Machining.

- Description: “Smart materials” change shape or properties when stimulated—like shape-memory alloys that return to a preset form when heated, or piezo materials that create voltage under stress (and the reverse).

- Key properties: Stimuli-responsive; often temperature-sensitive; can self-sense strain or heat.

- Machining challenges: Don’t overheat or overstress them during cutting; keep their function intact.

- Recommended strategy: Laser/EDM/ultrasonic finishing; gentle fixtures; set temperature/vibration limits; laser/EDM/ultrasonic finishing.

- Applications: Actuators, adaptive structures, medical devices.

- Supply Chain Note: Specialized low-stress machining and finishing for functional components.

19) Recycled & Sustainable Alloys: Machining and Traceability

Circular feedstock with composition variance; sustainability + traceability focus. Requires Adaptive CNC Strategies.

- Description: These are alloys made from recycled scrap. Composition can vary slightly between batches, so cutting behavior (chips/finish) may also vary a bit.

- Key properties: Near-primary performance; variability depends on sorting/refining.

- Machining challenges: Predictable Ra/IT; batch-to-batch tuning; certification needs.

- Recommended strategy: Inline spectroscopy → AI grade tagging → matching cutting parameters; robust deburr/finish plan; AI grade tagging.

- Applications: General fabrication, structural parts, fixtures, eco-product lines.

- Supply Chain Note: Adaptive machining strategies for material variability in sustainable supply chains.

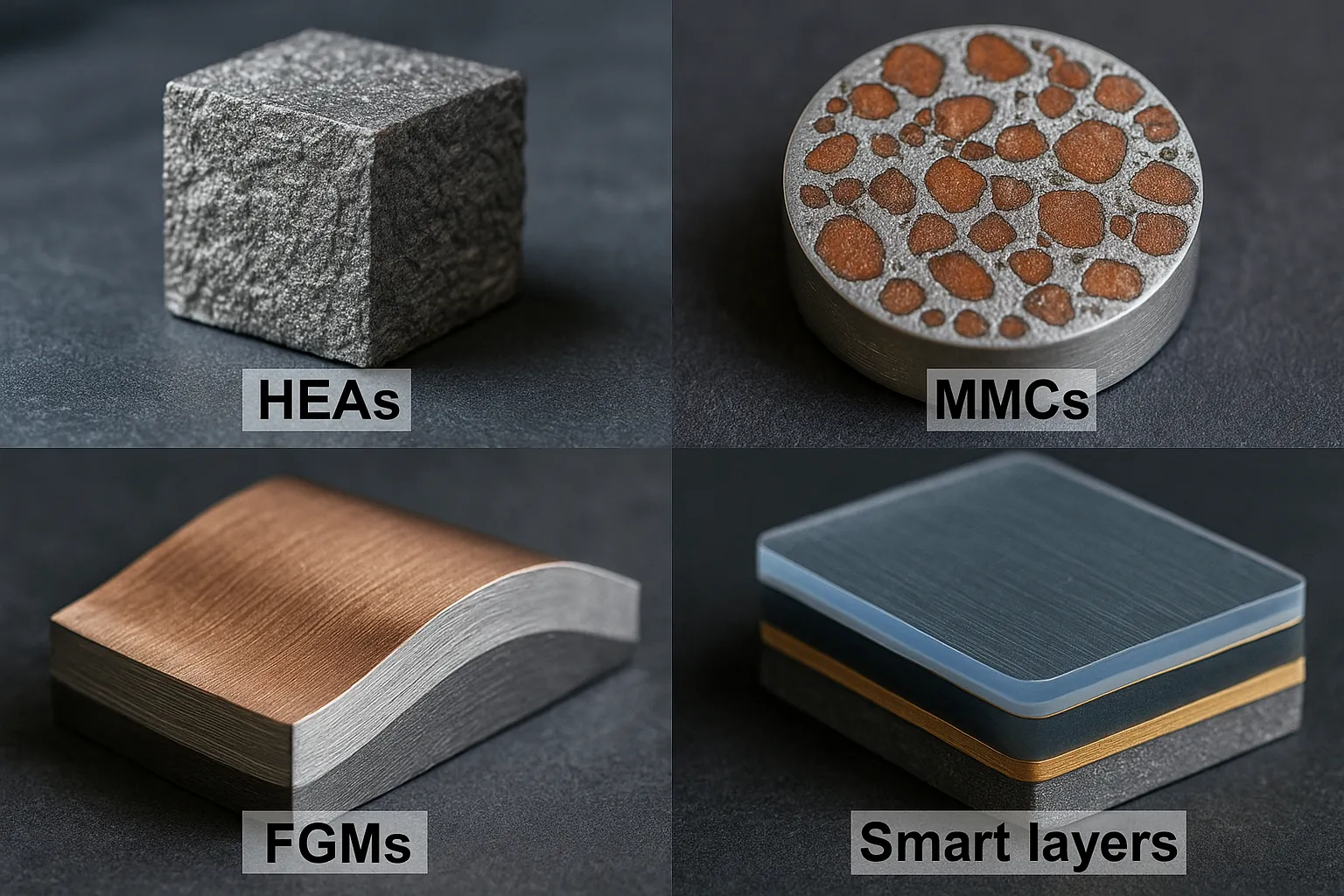

20) Metamaterials & Architected Lattices: Post-Processing and Finishing

Geometry-driven properties; often AM-made, then minimally machined/deburred. Requires 5-Axis CNC Finishing.

- Description: Metamaterials are structures where geometry (tiny repeating cells) controls behavior—like high stiffness to weight or sound absorption—more than chemistry does.

- Key properties: Ultra-light, anisotropic, thin struts; function set by cell design.

- Machining challenges: Fragile struts, access for tools, support & finishing.

- Recommended strategy: Gentle chip loads; media/abrasive flow finishing; hybrid DED repair + finish mill; hybrid DED repair.

- Applications: Aerospace panels, energy absorbers, implants.

- Supply Chain Note: Expertise in post-processing Additive Manufacturing (AM) parts and architected lattices.

21) Nano-Structured & Amorphous Alloys: High-Precision CNC Finishing for Advanced Properties

Bulk metallic glasses and nanocrystalline metals with exceptional strength/finish potential. Requires High-Precision CNC Finishing.

- Description: Amorphous (glass-metal) alloys don’t have a crystal pattern; nano-structured metals have very tiny grains. Both can be very strong and give smooth surfaces if you avoid heating them too much.

- Key properties: High hardness/strength; low k; risk of crystallization on overheating.

- Machining challenges: Heat-induced property loss; micro-cracking; crystallization risk.

- Recommended strategy: Cryogenic or low-heat cutting; fine finishing (grind/polish); laser polish for optics; laser polish for optics.

- Applications: Precision gears, optics mounts, medical tools.

- Supply Chain Note: High-precision finishing for amorphous and nano-structured components.

22) Bioinspired & Adaptive Materials: Gentle Machining for Functional Integrity

Self-healing polymers, hierarchical composites, and designs inspired by biology. Requires Gentle CNC Finishing.

- Description: These materials copy tricks from nature—like layers, fibers or micro-channels—to resist damage or carry fluids. Some can even self-heal small cracks.

- Key properties: Damage tolerance, damping, sometimes active response.

- Machining challenges: Keep functions intact (don’t crush channels; avoid heat that ruins polymers); functional integrity.

- Recommended strategy: Gentle removal (MQL/ultrasonic/laser), soft clamps, function tests after machining; function tests after machining.

- Applications: Safety structures, biomedical devices, smart tooling.

- Supply Chain Note: Gentle machining to preserve embedded functions in bioinspired and adaptive materials.

23) Surface-Engineered Coatings (DLC, TiAlN, etc.): Precision Finishing

Thin films to boost wear/oxidation; residual stress can cause delamination if mishandled. Requires Precision CNC Finishing.

- Description: Coatings are ultra-thin layers added to a surface (like TiAlN or DLC) to reduce friction or resist heat/wear. The trick is matching the coating to the base material so it doesn’t flake off.

- Key properties: Very hard, thin; possible brittleness; thermal mismatch with substrate.

- Machining challenges: Edge chipping, delamination, heat at the interface.

- Recommended strategy: Low-stress cutting; sharp tools; vibration monitoring; micro-finishing steps; vibration monitoring.

- Applications: Tooling, engine parts, medical instruments.

- Supply Chain Note: Precision finishing and coating application for wear-resistant parts.

24) Intelligent & Memory Materials — The Frontier of 2026+: Hybrid CNC Machining and Functional Integrity

Beyond “smart”: materials that can store a state, sense stimuli, and adapt shape/properties. The Frontier of CNC Machining.

- Description: Includes shape-memory alloys/polymers (remember a shape when heated), programmable metamaterials, neuromorphic oxides and hydrogels that “learn” repeated stimuli. Think materials acting like tiny sensors/actuators with built-in memory.

- Key properties: Stimuli-responsive, state memory, potential self-tuning.

- Machining challenges: Very sensitive to temperature/strain; must preserve function while machining; state memory.

- Recommended strategy: Hybrid shaping (laser/ultrasonic/EDM); live temperature/vibration limits; in-situ function tests; in-situ function tests.

- Applications: Soft robotics, adaptive structures, implants, smart dampers.

- Supply Chain Note: Frontier machining capabilities for next-generation intelligent materials.

Comparative Property Table: Advanced Materials Reference for CNC Machinists

| Material | Density (g/cm³) | Hardness (HV) | Thermal Conduct. (W/m·K) | Machinability Index* |

|---|---|---|---|---|

| Aluminum 7075 | 2.8 | 150 | 130 | 1.0 |

| Brass (CuZn37) | 8.4 | 100 | 110 | 1.2 |

| Steel AISI 1045 | 7.8 | 180 | 50 | 0.8 |

| Hardened Steel (60 HRC) | 7.9 | 700 | 25 | 0.3 |

| Inconel 718 | 8.2 | 420 | 12 | 0.25 |

| Titanium Ti-6Al-4V | 4.5 | 340 | 7 | 0.35 |

| HEA (CoCrFeNiMn) | 7.9 | 320 | 15 | 0.35 |

| MMC (Al–SiC 20%) | 2.9 | 250 | 120 | 0.45 |

| Amorphous Alloy | 6.9 | 600 | 10 | 0.20 |

*Index relative to free-machining steel ≈ 1.0. Values are indicative ranges; refine per specific grade/spec sheet.

Future 2026 Trends: AI Integration and Adaptive CNC Machining

- Cryogenic hybrid machining: LN₂ jets for Ti/HEAs → −40% tool wear, stable Ra.

- Laser-assisted ultrasonic milling: heat softening + vibration → ceramics/MMCs enabled.

- Neuromorphic control loops: near-spindle models suppress chatter in milliseconds.

- Sustainable MQL 2.0: bio-based coolants, low VOC, better residue behavior.

- Self-learning digital twins: model-reality deltas auto-tune feeds, reduce first-off risk.

See also: Machining Processes 2025–2026 — Complete Illustrated Guide (AI & Hybrid)

Process-first reference with photos, WEBP schematics, AI recipes, hybrid/2025 innovations, and quick tables.

Open the machining guide →

Frequently Asked Questions (FAQ) on Advanced Materials Machining

- Q: What is the biggest challenge in machining advanced materials (e.g., Inconel, Titanium)?

A: The biggest challenge is managing heat and tool wear. Advanced materials, especially superalloys, have low thermal conductivity, concentrating heat in the tool and workpiece, leading to rapid tool wear and material damage risk.

- Q: What is "Work-Hardening" and how does it affect CNC machining?

A: Work-Hardening is when a material becomes harder and stronger as it is deformed (cut). This is common in stainless steels and Nickel alloys. If the tool does not cut beneath the work-hardened layer, it wears out quickly. The recommended strategy is high feed rates and high machine rigidity.

- Q: Why is cryogenic machining necessary for Nickel or Titanium alloys?

A: Cryogenic machining (using liquid nitrogen) drastically reduces the temperature in the cutting zone. This helps to: 1) Prevent material sticking to the tool (built-up edge). 2) Improve tool life. 3) Maintain the dimensional stability of the part.

- Q: What are the advantages of using CNC Milling for Metamaterials and lattice structures?

A: Metamaterials and lattice structures are extremely fragile. High-precision 5-axis CNC milling is essential for post-processing Additive Manufacturing (AM) parts, ensuring minimal material removal and finishing critical surfaces without damaging the delicate internal structures.

- Q: What types of tools are used for machining MMCs (Metal Matrix Composites)?

A: MMCs are highly abrasive due to ceramic particles (e.g., SiC). Super-abrasive tools, such as PCD (Polycrystalline Diamond), are necessary to prevent rapid wear of carbide tools.

- Q: How can traceability be ensured when machining recycled alloys?

A: Traceability is ensured through inline spectroscopy and AI-based grading systems. These technologies monitor material composition in real-time to adjust cutting parameters and maintain quality despite batch variations.

- Q: What is "Adaptive CNC Machining" in the context of advanced materials?

A: Adaptive CNC machining involves using sensors (for vibration, temperature, force) to automatically adjust feed rate and depth of cut during the process. This is vital for Functionally Graded Materials (FGMs) or alloys with unpredictable behavior.

- Q: What is the role of Wire-EDM (Electro Discharge Machining) in processing hard materials?

A: Wire-EDM is used to cut extremely hard materials (e.g., Carbides, Hardened Steels) without mechanical contact. It is ideal for achieving complex geometries, sharp corners, and high-precision finishes without inducing stress or micro-cracks.

- Q: Where can I get CNC machining services for custom parts based on a drawing, using these advanced materials?

A: Inotech Machining offers project management and intermediation services, facilitating the machining of custom parts based on demand drawings. We connect EU clients (DACH, France, Nordic countries) with high-precision manufacturing suppliers in Romania, ensuring quality and cost efficiency for a wide range of materials, including advanced ones.

References & Further Reading — Advanced Materials

Core Materials Handbooks (general):

- ASM Handbooks — Overview by Volume — Canonical reference set used across this article.

- ASM Handbook, Vol. 16 — Machining — Conventional & non-traditional processes, abrasives, tool materials, fluids.

Steels & Stainless Steels (machining & selection):

Core references for carbon/alloy steels and stainless — grades, properties, feeds/speeds, tooling, cooling.

- ASM Handbook, Vol. 1 — Properties & Selection: Irons, Steels & High-Performance Alloys

- Machining of Stainless Steels & Super Alloys (Wiley)

Aluminum Alloys (machining & designation):

Quick sources for 2xxx/6xxx/7xxx families, tempers, and machining windows (HPC, MQL/cryo when relevant).

Copper Alloys — Brass/Bronze/CuNi (machinability & process windows):

Authoritative data for free-cutting brasses, bronzes and CuNi — speeds/feeds, tool choices and finish targets.

- ASM Specialty Handbook — Copper & Copper Alloys

- CDA: High-Speed Machining of Brass

- DKI/CDA: Recommended Machining Parameters for Copper Alloys

Magnesium Alloys (machining & integrity):

Lightweight alloys (AZ31/AZ91): high speed windows, chip ignition safety, burr control and surface integrity.

- ASM Handbook — Properties & Selection: Nonferrous Alloys

- Machining of Light Alloys: Aluminum, Titanium, and Magnesium (Routledge/Taylor & Francis) — State-of-the-art on machining of Al/Mg/Ti, convențional & non-tradițional.

Cobalt-Chrome (Co-Cr) — difficult-to-cut:

Medical/aerospace: tool wear, minimum chip thickness, coolant strategy (HPC vs MQL/cryo).

- Machinability of Cobalt-based and Cobalt Chromium Alloys — Review (UTM)

- Impact of Cutting Data in Sintered Cobalt Turning — Materials (2024)

Tool Steels & Hardened Steels (>45 HRC):

Hard milling vs grinding trade-offs, PCBN/ceramic tools, HAZ control and finish targets.

- ASM Handbook, Vol. 16 — Machining

- Grinding Technology: Theory and Applications of Machining with Abrasives — S. Malkin

Nickel Alloys & Inconel (machining):

Difficult-to-cut Ni-based alloys: HEM strategies, fluids, force/temperature management.

- High-Efficiency Milling of Inconel 718 (2025)

- Modelling machinability of INCONEL® (2024)

- Cutting fluids in finish turning of Inconel 718 (2025)

Titanium Alloys (cooling & processes):

α / β / α+β grades; cryo/CO₂ vs wet/dry, tool wear and integrity.

High-Entropy Alloys (HEAs):

Processing routes, properties and implications for machining strategy and tool choice.

Metal Matrix Composites (MMCs):

SiCp/Al and other MMCs — PCD/diamond tooling, parameter windows, wear.

Functionally Graded Materials (FGMs):

Fabrication routes and post-processing implications for adaptive machining.

Amorphous & Nano-Structured Alloys (BMGs):

Conventional vs non-traditional machining, thermal softening and integrity risks.

- Machining of Bulk Metallic Glasses — Review (2024)

- Manufacturing of metallic glass components (2024)

Ceramics & Hardmetals (Si3N4, SiC, Al2O3, WC-Co):

Diamond/CBN tooling, ductile-regime cutting, ultrasonic-assisted machining and grinding strategies.

- Machining of Advanced Ceramics (Springer)

- CVD Diamond Processing Tools — Review (2024) — Applications of diamond tools for precision finishing and micro-machining.

- Abrasive Machining of SiC Ceramics — Review (2024) — Diamond/ultrasonic techniques, accuracy, and tool wear.

- Grinding Mechanics of Ceramics — Review (2025) — Force models and guidelines to minimize subsurface damage.

Polymers & High-Performance Thermoplastics (PEEK/PEI):

Low cutting temperatures, sharp edge geometry, chip evacuation and cooling to avoid smearing & drift.

- Forming and Machining of Polymers, Ceramics, and Composites (CRC/Taylor & Francis, 2024) — Recent developments in the processing and machining of nonmetallic materials.

- Victrex PEEK — Processing & Machining Guide — Official recommendations for machining, pre-drying, and finishing.

- Recent Advances in PEEK — Review (2025) — Properties, processing, and implications for machining.

Fiber Composites (CFRP/GFRP):

Delamination-free drilling/milling, PCD/diamond-coated cutters, stack drilling (Ti/CFRP).

- Machining of Polymer Composites — J. Ahmad (Springer) — Classic reference for CFRP/GFRP machining.

- Machining of Polymer Composites (CFRP/GFRP/NFRP) — Review (2023) — Delamination, tool wear, parameter windows, and strategies.

- FRTP Composites Machining — Review (2024) — Damage mechanisms and challenges (CFRP/PEEK).

Metamaterials & Lattice Structures — Post-Processing:

Finishing of internal/complex features: AFM, grinding, ECM for LPBF lattices.

- Abrasive Flow Machining of BCC lattices (2024)

- Abrasive machining & finishing of AM metals — Review (2025)

- Post-processing of complex AM parts — Review (2024)

Recycled & Sustainable Alloys — Variability & Traceability:

Scrap-to-high-performance routes and in-line chemistry monitoring for stable machining.

Cooling Strategies (Cryogenic/MQL):

Evidence on cryo (LN₂/CO₂), MQL and HPC for tool life, Ra and energy.

Bioinspired & Adaptive Materials: Gentle Machining for Functional Integrity

Nacre-like, lattice and gradient architectures benefit from low-force, low-heat finishing to preserve functional structures.

- Bioinspired designs for lightweighting — Critical review (2025)

- Bio-inspired structural materials — Recent advances (2025)

Surface-Engineered Coatings (DLC, TiAlN, etc.): Precision Finishing

Tool-coating selection drives wear, BUE, heat and finish in advanced alloys (DLC for non-ferrous; TiAlN/AlTiN/CVD for ferrous/high-temp).

- DLC top-layered over TiAlN/CrN — Tool wear & life (2024)

- New-generation CVD/PVD tool coatings — Review (2023)

- PVD technology for coated cutting tools — Review

Intelligent & Memory Materials — The Frontier of 2026+: Hybrid CNC Machining and Functional Integrity

NiTi/SMAs and smart materials require hybrid/low-damage routes (laser/ECM/EDM + light finish cuts) to retain transformation behavior.

- Nickel–Titanium laser micromachining — Review (2024)

- Micro-machining of NiTi SMAs — State-of-the-art (2025)

- Cutting of NiTi — Review (2024)

- Shape Memory Alloys in modern engineering — Overview (2025)

Sources & Methodology

Content is compiled from peer-reviewed journals (e.g., CIRP Annals – Manufacturing Technology, Elsevier/Springer/MDPI reviews), authoritative handbooks (ASM International: Machining; Materials Properties), research from leading institutes (MIT, Fraunhofer, ETH Zurich) on high-entropy alloys, titanium/nickel machining and metamaterials, and validated industry data (tooling OEM catalogs, machining application notes, machine tool specifications). Where applicable, we reference standards (ISO 3002, ISO 21920, ISO 1832/513) and recent studies on cryogenic/MQL cooling, adaptive/hybrid machining, and surface integrity.

Disclaimer: Values and recommendations are indicative and context-dependent. Always verify with current standards, OEM data, and a qualified materials specialist for critical parts.