PLASMA CUTTING SERVICES

Precision Plasma Cut Parts for Industrial Applications

We use state-of-the-art plasma cutting equipment to deliver precise and reliable results for a wide range of industries.

- High-Accuracy Laser Cutting for Steel, Stainless, and Aluminum.

- Integrated with Full Machining & Fabrication.

- ISO-Compliant Quality and Traceability.

- Trusted by aerospace, automotive, food processing, and machinery manufacturers.

Plasma cutting trusted by European manufacturers in demanding industries.

Based in Romania and serving clients across Europe, we are a trusted partner for companies requiring high-quality metal components for complex machinery and production systems. From machine frames to precision-cut structural parts, our plasma cutting capabilities support sectors with high technical and operational demands. We collaborate with manufacturers of special machines, production lines, and industrial tooling for the automotive, aerospace, and pharmaceutical industries.

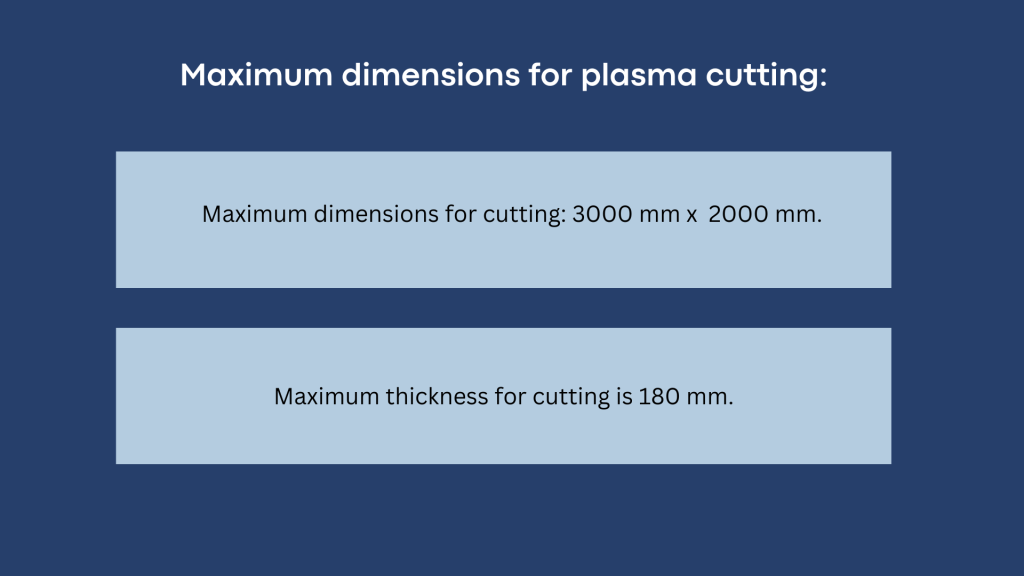

Plasma cutting maximum dimensions we can execute:

What is plasma cutting?

Whenever the thickness of the metal sheet parts/flat metal parts is bigger than 20 mm, plasma cutting is the ideal technique for processing.

CNC plasma cutting uses a jet of heated gas to cut through metals aluminum or steel), achieving precise tolerances (+/- 2mm) in materials up to 80mm thick.

This technology also offers a range of additional services, including bevelling, drilling, tapping, countersinking, and edge milling.

For heavy plate processing, oxy-cutting is an excellent choice, delivering high precision when working with large, thick plates.

What are the advantages of custom plasma cutting?

- Fast cutting

Plasma cutting is known for its speed. It can cut through materials quickly compared to other traditional methods.

- High productivity

Due to its fast cutting ability, plasma cutting increases productivity, making it ideal for high-volume production.

- Precision and accuracy

Plasma cutting produces clean, precise cuts with minimal slag, reducing the need for post-cutting cleanup.

- Minimal Material Waste

The precision of the plasma cutter and the narrow kerf result in less wasted material compared to other cutting methods.

- Wide Range of Materials

Plasma cutting can be used to cut a wide variety of metals, including steel, aluminum, brass, copper, and stainless steel. It is effective on both thin and moderately thick materials.

- Can cut thick metal parts

Plasma cutting machines are capable of cutting metal parts/sheets from 1mm (or less) up to 50mm or more.

Types of materials we can cut using plasma technology:

Steel

Plasma cut steel parts.

Stainless Steel

Plasma cut stainless steel parts.

Aluminum

Plasma cut aluminum parts.

Click the yellow button, upload your files and get a FREE quotation.

All uploads are secure and confidential.